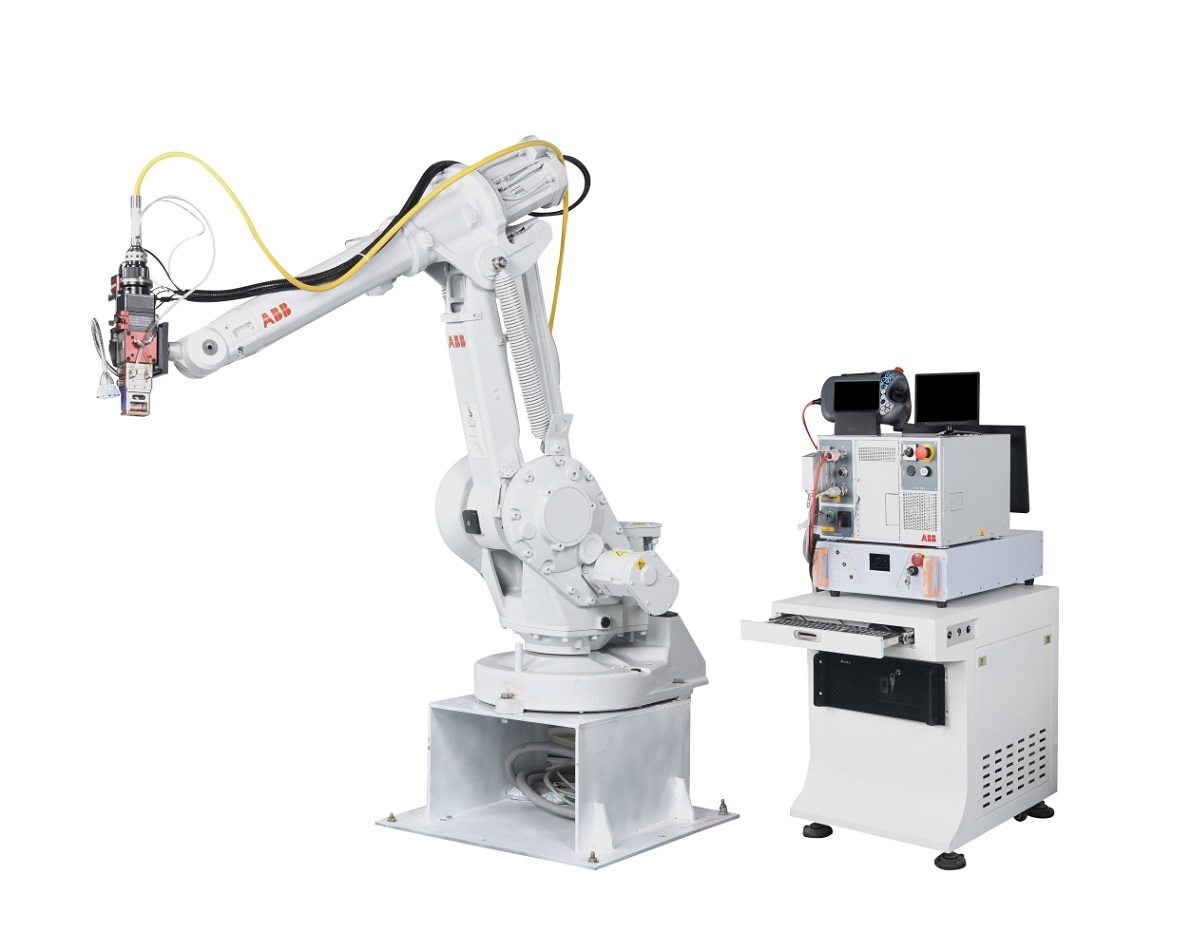

Slewing bearing itself has the characteristics of compact structure, convenient guide rotation, easy installation and easy maintenance, and is widely used in mobile robots, spot welding robots, welding robots, palletizing robots, laser processing robots, assembly robots, handling machine and other parts of industrial robots.

|

|

Robots are classified by slewing bearings

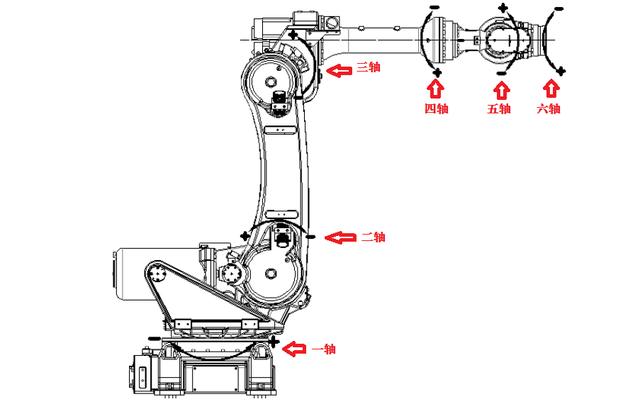

The common slewing bearing device structure of modern industrial robots has the following three kinds: split slewing bearing structure, integrated slewing bearing structure, mixed slewing bearing structure.

Split type slewing support structure:

Mainly on the structure of industrial robots by using cross roller slewing bearing overturning moment, axial force and radial force, including dynamic and static conditions, driving speed reducer only bear the rotation of the rotating shaft torque, so the requirements under the condition of crossed roller slewing ring bearing high precision, and to ensure that the rotation accuracy of the robot.

Integral slewing bearing structure:

It adopts the main bearing reducer with sufficient bearing capacity in the structure. The main bearing of the reducer bears all the overturning torque and axial force of the industrial robot, so that it does not need to cross the roller slewing bearing. The main bearing of the reducer provides high precision, but the cost of the reducer is relatively expensive.

Hybrid slewing bearing structure:

Its structural characteristics are that hollow main bearing reducer with certain bearing capacity and cross roller bearing with certain accuracy are used to complete the functions of supporting and rotary. Turntable at the same time of the industrial robot and rotary transmission reducer output shaft panels and cross roller bearing inner ring fixed connection, crossed roller slewing ring bearing stiffness is greater than that of reducer output panel bending stiffness, so under dynamic conditions, bending moment and axial force moment is mainly composed of crossed roller slewing bearing to carry. In this way, the static bearing accuracy is guaranteed by the main bearing of the reducer, so the accuracy of the cross roller bearing does not need to be as high as the kind of split structure. It is possible to obtain a high cost performance ratio due to its affordable price. Is widely used in those high speed, high precision, heavy load loading and unloading robot, assembly robot, palletizing robot and so on.