1. Structural features:

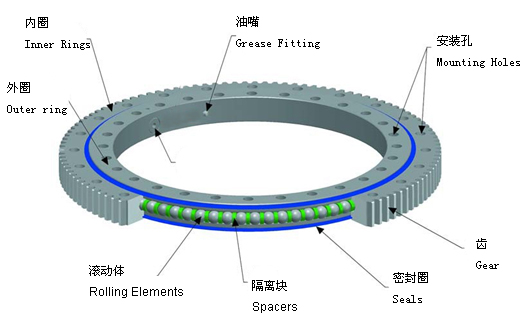

Rotary bearing consists of ring (inner ring, outer ring, upper and lower ring), rolling body, isolation block, sealing ring and nozzle, etc.

The rotary bearing can bear large axial load, radial load and overturning H moment and other comprehensive loads at the same time. The inner and outer rings of the rotary bearing have mounting holes, lubricating oil nozzles and sealing devices. The inner and outer ring bolts are respectively connected with the base and rotary part of the main engine, which has the characteristics of compact structure, simple installation and easy maintenance. It can meet the different needs of all kinds of main machines under different working conditions, so it is widely used in various large and heavy machinery rotary devices.

Single row four-point contact ball, double row reducing ball, cross cylindrical roller, three-row cylindrical roller bearing, etc., all kinds of bearings can be provided with toothless, external or internal structure products according to the requirements of users.

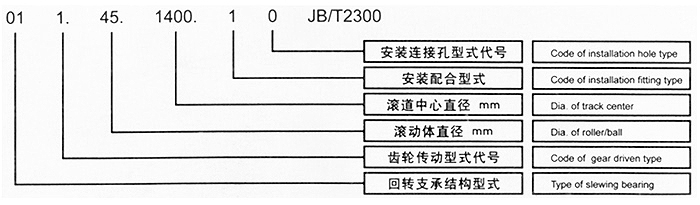

2. Code name:

3. The material

Materials for rings and rolling bodies

In general, the rolling body of turntable bearing is made of GCr15 or GCr15SiMn bearing steel in accordance with GB/T18254, and the ring is generally made of 50Mn steel. In special applications, 42CrMo alloy structure steel in accordance with GB/T3077 has been tempered and tempered or normalized.

Cage material

The turntable bearing cage type has the whole cage, the segment type or the isolation block type cage and other different structures, according to its structure and application of different, respectively using different materials, mainly has its 20 steel, ZL102 cast aluminum alloy, polyamide 1010, resin ZL102, nylon GRPA66.25 brass and aluminum bronze.

Sealing ring material rotary bearing sealing ring material is made of oil resistant butadiene rubber. HONOR 20QUAD CAMERA

4. Materials for cage

Brass and aluminum bronze.

5. Sealing ring and material

Rotary bearing seal ring is made of oil resistant butadiene rubber

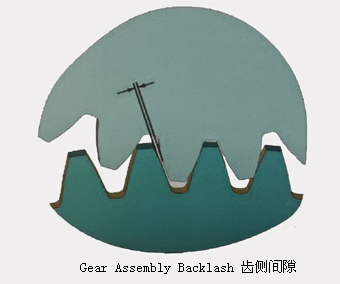

6. Clearance

The clearance of turntable bearing is mainly used to compensate the manufacturing error and installation error of turntable bearing parts and relevant host assembly parts to ensure the normal use of bearings. The clearance of turntable bearing is related to its structure type, tolerance grade and pitch diameter of rolling body group, and the specific data are listed in the technical parameters of different series

7. Gear engagement

Usually the pinion meshing with the turntable bearing gear is supported only at one end. In the case of high meshing transmission load, the following aspects should be paid attention to in order to prevent the early deactivation of the gear:

A. Addendum circle correction: it is especially important for pinion with small number of teeth to prevent root cutting caused by interference between addendum and involute.

B. Contour and tip edge trimming: For high dynamic load, it is possible to deform the profile of small and medium gears and teeth at work, and the tooth profile and tip edge trimming in advance can avoid the occurrence of root cutting.

C. The hardness of gear: because the number of working cycles of pinion is much higher than the tooth, to make its life match with the tooth ring, it is necessary to put forward higher requirements on its material, toughness, hardness, etc. Therefore, when adopting the overall quenching, attention should be paid to not being too hard to prevent brittleness under large torque and impact load. When surface quenching is adopted, stress concentration of root should be taken into account in addition to root strength.