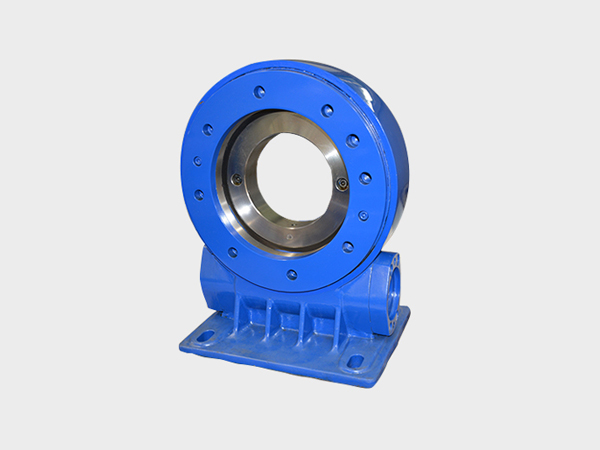

Vertical rotary reducer Product features: 1. The product adopts blind hole design and skeleton oil seal sealing structure, reliable sealing performance, sealing place can avoid direct sunlight, effective dust-proof, waterproof, protection grade up to IP 65, suitable for outdoor use, can be single flange or double flange output. 2. Thyroidal worm is produced by special machine tools and equipment with multi-tooth contact, which can transfer larger torque and bear larger axial force, radial force and tipping moment. 3. The design of the product adopts the universal size at home and abroad, which is convenient for replacement.

Application scope:

It is mainly used for rotation of pitch direction of solar tracking system, and can also be used for rotation of some special construction machinery and industrial equipment.

• Rotation of pitch position of solar power generation system such as flat uniaxial, oblique uniaxial, trough power generation and concentrated light power generation.

• Automatic feeding machine and other industrial equipment.

Application advantages:

1. The vertical structure effectively simplifies the complex structure design of solar energy horizontal rotary drive, which requires additional support, and reduces the cost of the overall system.

2. The surface of the product is treated by multi-process secondary electrostatic powder spraying, using epoxy zinc-rich primer and epoxy resin flour, which greatly improves the anti-corrosion and anti-aging ability of the product. Neutral salt spray test for more than 1000 hours.

3. The rotary bearing raceway and gear tooth surface are hardened, high hardness and strong rigidity.

4. The service life can reach 25 years.

5. With self-locking function, improve the safety of use.

6. The transmission accuracy can reach 1 milliradian (1MRAD).

7. The product is based on the purpose of maintenance-free development, minimal maintenance.

8. The load and tilting moment of the product are greater than those of similar products in the market.

9. After high and low temperature test, the product has strong temperature difference resistance.

10. Using national high-tech graphene to synthesize grease, its life and heat dissipation efficiency are far more than ordinary grease.

11. Toroidal worm design, multi-tooth contact, bearing large output torque.

Performance parameter comparison table:

| specifications | Reduction ratio | The output torque KN.M | Overturning moment KN.M | Keep the moment KN.M | Axial load (static) KN |

Axial load (moving) KN |

Radial load KN | Radial load KN | precision | Since the lock | weight | efficiency |

| (KG) | ||||||||||||

| 3" | 62 | 0.4 | 0.5 | 2.1 | 14.7 | 4.8 | 8.3 | 4.2 | 0.15 | Yes | 17 | 40% |

| 5" | 62 | 0.6 | 3.508 | 5 | 45 | 13.8 | 22.6 | 11.8 | 0.15 | Yes | 45 | 40% |

| 7" | 71 | 1.2 | 9.489 | 10.06 | 133 | 32 | 53 | 28 | 0.15 | Yes | 37 | 40% |

| 9" | 61 | 6.5 | 31.5 | 36 | 338 | 81 | 120 | 61 | 0.15 | Yes | 58 | 40% |

| 14" | 85 | 8 | 47.46 | 45 | 553 | 133 | 220 | 117 | 0.15 | Yes | 134 | 40% |

| 17" | 102 | 10 | 94.992 | 65.6 | 970 | 235 | 390 | 205 | 0.15 | Yes | 150 | 40% |